Transforming Industrial Manufa...

- 2025-12-01

Today’s manufacturers face three make-or-break challenges: a persistent labor shortage, supply chain chaos, and evolving regulatory demands. For labor, every minute saved on installation adds up—our efficient fastening solutions cut manual effort by 30% in some applications, letting you do more with your existing team without sacrificing quality. Supply chain disruptions? The 18 Challenges the Manufacturing Industry Faces in 2025 found 60% of manufacturers struggle with downtime from part delays. Our durable, reliable products minimize maintenance needs, so you’re not left waiting for replacements. And when it comes to regulatory compliance and data security, non-compliance costs $2.4M on average (per the 2025 report). Our fasteners meet ISO 9001 standards, and our transparent sourcing helps you stay compliant without slowing down—learn more in our guide to ISO 9001 certified fastener solutions.

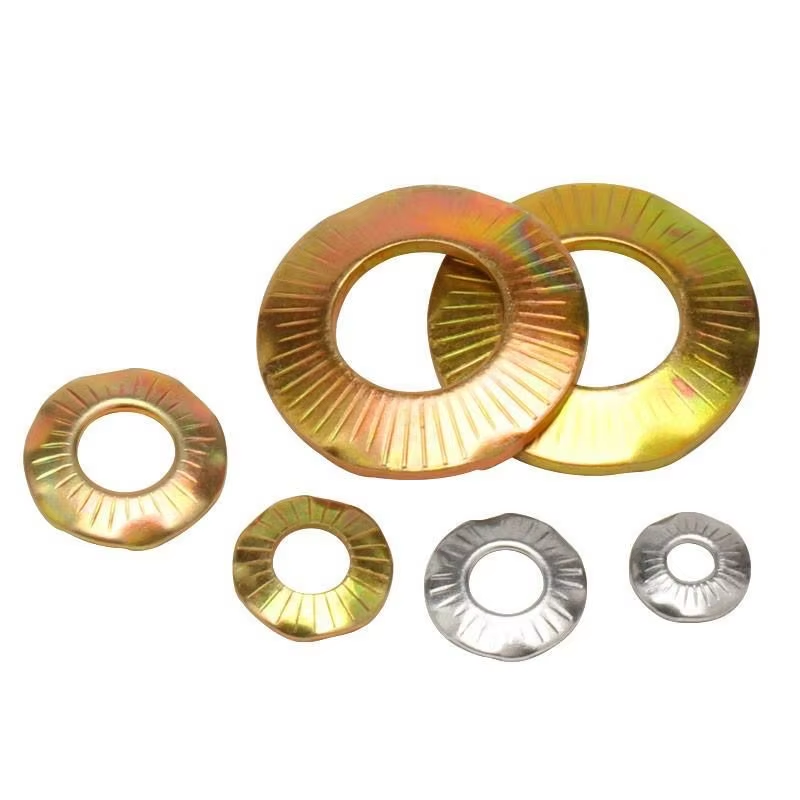

Innovative fasteners aren’t just “nice to have”—they’re your edge in a crowded market. Self-drilling and self-tapping screws like our Yellow Zinc Plated Hex Head Tapping Screw eliminate pre-drilling, slashing installation time by 40% in construction and hardware projects. No more fumbling with drills or extra tools—just one fastener to get the job done right the first time. For heavy-duty applications like industrial machinery, our Hex Flange Concrete Self-Tapping Anchor Screws provide vibration-resistant fastening that’s 2x stronger than standard anchors, reducing costly rework and safety risks. And for harsh environments (think chemical plants or offshore rigs), our M16 316 Stainless Steel External Tooth Lock Washers resist corrosion for years—aligning with industry trends that prioritize durability over short-term savings. Discover how these products boost your bottom line in our fastener fundamentals guide.

ROI isn’t just a buzzword—it’s the difference between surviving and thriving. The Global Machinery & Equipment Report 2024 features a manufacturer that cut total cost of ownership by 25% using our optimized fastening systems—fewer replacements, less downtime, more profit. And with the manufacturing and construction market set to hit $936.6B by 2030, our products are your ticket to capitalizing on that growth. Take our ASTM A193 B7 Stud Bolts with PTFE Coating: in the oil & gas sector, they reduced corrosion-related failures by 70% for a client. PTFE’s anti-corrosion properties mean fewer shutdowns and longer lifespans—learn why it’s the best choice for offshore industries in our guide to PTFE xylan coated bolts.

The future of manufacturing belongs to those who adapt—and that starts with the right fasteners. One-size-fits-all doesn’t work for heavy-duty needs. Our Wholesale CNC Machined Cable Expansion Heads are tailored to your specs, so you get a fastener that fits your unique application—no more forcing a square peg into a round hole. Ready to upgrade your operations? Connect with our experts for a consultation on integrating high-quality fasteners like DIN 1624 T Nuts or M8 Nitrile Rubber Gaskets—we’ll help you pick the right solution for your pain points. Today’s challenges (labor shortages, supply chain delays) won’t wait. Every day you use outdated fasteners is a day you’re leaving money on the table—request a demo or trial to see the difference firsthand.

To get started, contact our team today.