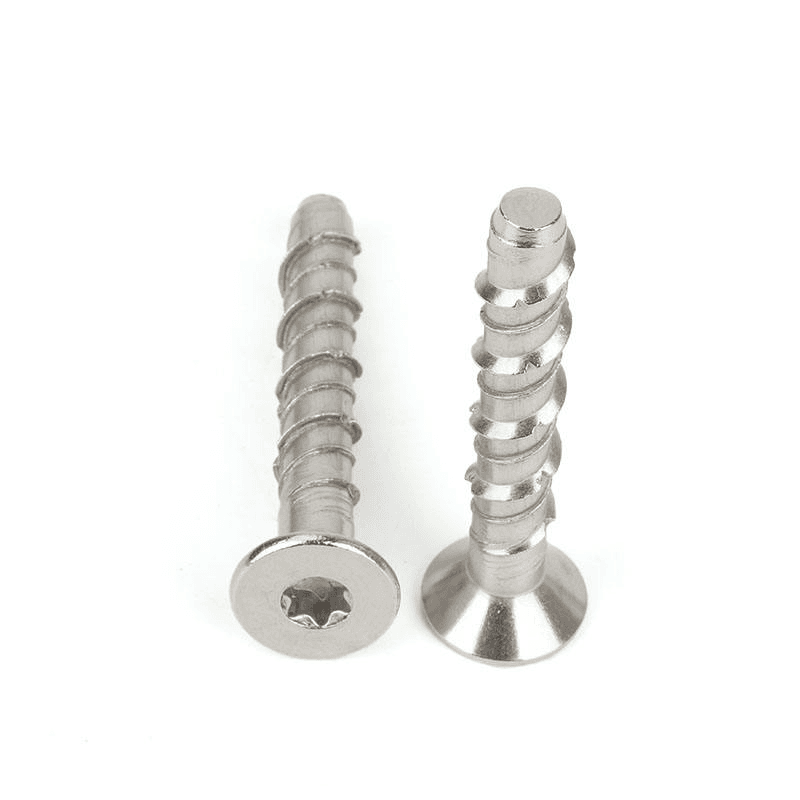

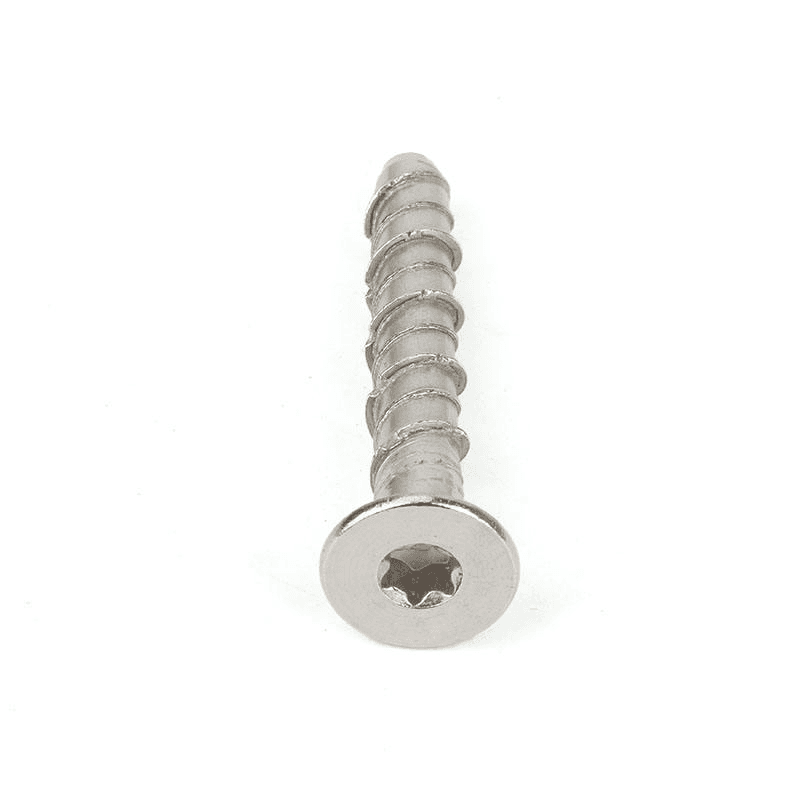

Stainless Steel Double Thread Torx Countersunk Head Concrete Self-tapping Screw

Product Description

This double thread stainless steel concrete screw is a high-performance self-tapping anchor specially designed for directinstallation into concrete, brick, and stone.Its dual-thread cutting design features two independent thread pitches — the outer coarse thread cuts into the concrete for strongmechanical interlock, while the inner fine thread stabilizes the screw and reduces installation torque.The countersunk head ensures a flush, clean finish after installation, and the Torx or hex socket drive provides excellent torquetransmission without cam-out.Manufactured from A2 (304) or A4 (316) stainless steel, it offers superior corrosion resistance and long-term durability even inoutdoor or marine environments.

Product Advantages✅ Double thread design for faster installation and higher pull-out strength✅ No plastic anchor or chemical adhesive needed✅ Excellent corrosion resistance for outdoor and humid environments✅ Flush installation with countersunk head design✅ Anti-slip Torx drive for stable tightening✅ Removable and reusableTypical ApplicationsFastening of steel plates, brackets, or profiles to concrete Electrical and mechanical installations Mounting window frames, façades, and railings Construction and infrastructure projects Outdoor and marine anchoring systems

| Brand Name | hangfan |

| Industry Experience | Over 20 years (focused on fastener R&D, production, and sales, with mature full-process service capabilities covering design,material selection, and delivery) |

| Number of Employees | 160+ (including R&D, production, quality inspection, and sales teams; R&D and quality inspection personnel account for over 30%, with core members having 10+ years of industry experience) |

| Global Certifications | - Quality Management: IATF16949 (automotive-specific), ISO9001- Environmental & Occupational Health: ISO14001, ISO45001- Industry-Specific: PED-EN10204, CPREN14399, EN15048, AD2000 |

| Main Materials | - Stainless Steel: 304 (general corrosion resistance), 316 (enhanced corrosion resistance for marine/chemical use)- Alloy Steel (high-strength material, suitable for heavy-load scenarios such as engineering machinery and automotive key components)- Carbon Steel (cost-effective, applicable to general mechanical connection scenarios with no special requirements for corrosion resistance or high strength) |

| Surface Treatment | - Basic Rust Prevention: Plain, Black Oxide, Zinc Plated, Hot Dip Galvanized- High-End Functional: PTFE Coating, Passivation, Nickel Plating, Chrome Plated, Copper Plating, Delta/Daromet, Threadlockers, Wax Plated, Anodize |

| Product Range (Fasteners) | - Standard: Bolts (hexagon, high-strength, carriage), Nuts (hexagon, lock, flange), Washers (flat, spring, combination), Screws (self-tapping, machine, set)- Non-Standard: Custom parts per drawings/samples- Industry-Specific: Auto high-strength bolts, energy-resistant fasteners, infrastructure anchors |

| Main Production Equipments | CNC Machining Centers, Cold Heading Machines, Heat Treatment Equipment, Hot Forging Machines, Thread Rolling Machines (covering forming, strengthening, and thread processing for mass production and precision customization) |

| Inspection Instruments | - Mechanical Property: Tensile Testing Machine, Hardness Tester, Torque Tester, Impact Tester, Fatigue Testing Machine, Universal Testing Machine (UTM)- Environmental Adaptability: Salt Spray Test Chamber, Vibration Testing Machine- Precision & Composition: Coordinate Measuring Machine (CMM), Optical Sorting Machine, Spectrometer, X-ray Fluorescence Analyzer (XRF)- Routine Dimension: Micrometer, Caliper, Thread Gauge, Profile Projector, Go/No-Go Gauge |

| Packaging Solutions | - Standard: Carton + Pallet (suitable for sea/land transport, easy for warehouse stacking)- Custom: Small packaging (bagged/boxed), printed packaging, anti-damage cushioning packaging (per customer needs) |

| Technical Services | - Material selection recommendations (based on application scenarios)- Non-standard fastener design support (optimizing connection solutions to reduce costs)- Provision of quality reports (material analysis, salt spray test, etc.) |

FAQ

Q1:How many coutries you already exported ?

A1:Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt, Turkey,Jordan,etc.

Q2:How can l get some samples?

A2:Small samples in store and can provide the samples for free. Catalgue is available, most patternswe have ready samples in stock.Customized samples will take about 5-7days.

Q3:What is the delivery ?

A3:Sample order's delivery time is 5-7 days. Container orders are about 15-20 days